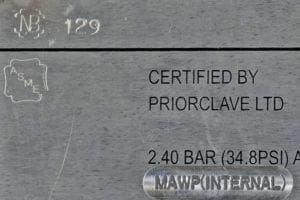

Priorclave are one of the very few sterilizer manufacturers in the world who retain complete control of their supply chain by manufacturing all principal components in-house. Other autoclave manufacturers have bolstered profit margins by outsourcing many components—including the fabrication of pressure vessels—to the developing world. Priorclave continue to make their own chambers exclusively in their Southeast London facility. These high-quality 316L stainless steel vessels meet both European standards and the stringent standards of the ASME Boiler and Pressure Vessel Code.

All Priorclave autoclaves comply with national US, Canadian, UK, and EU safety regulations. They are manufactured under an ISO 9001:2008 quality management system in our UKAS-accredited facility. Our autoclaves and control systems are ETL listed and EMC certified, and feature ASME-stamped pressure vessels. These pressure vessels are manufactured entirely in-house, and tested to 1.5 times their maximum working pressure. They have full insurance approval for pressure vessel design and construction and are CE Marked under the Pressure Equipment Directive PD5500:2000 Cat 3, Certificate Number SS42059010-2 Rev 1. They also conform to the general requirements of BS 2646 and are CE Marked for BS EN61010-2-41, Low Voltage and Electromagnetic Compatibility.

All Priorclave autoclaves comply with national US, Canadian, UK, and EU safety regulations. They are manufactured under an ISO 9001:2008 quality management system in our UKAS-accredited facility. Our autoclaves and control systems are ETL listed and EMC certified, and feature ASME-stamped pressure vessels. These pressure vessels are manufactured entirely in-house, and tested to 1.5 times their maximum working pressure. They have full insurance approval for pressure vessel design and construction and are CE Marked under the Pressure Equipment Directive PD5500:2000 Cat 3, Certificate Number SS42059010-2 Rev 1. They also conform to the general requirements of BS 2646 and are CE Marked for BS EN61010-2-41, Low Voltage and Electromagnetic Compatibility.

Ensuring Quality

Priorclave’s manufacturing incorporates:

Priorclave’s manufacturing incorporates:

- An ISO 9001 Quality Management System, covering:

- Boilers and Process Plant Fabrication

- Prevision Machining and General Fabrication

- Electrical Instruments and Control Systems

- Equipment Installation and Service

- Full EMC Compliance Testing

- Monitored approval of vessel design and welding procedures to the requirements of the European Pressure Equipment Directive 97/23/EC

- UKAS Accreditation as a Calibration Laboratory

Priorclave Safety Standards:

Priorclave Safety Standards:

- All pressure vessels are manufactured in-house and tested to 1.5 times their maximum working pressure

- All Priorclaves are fitted with pressure interlocks

- To protect against certain hazards when sterilising liquid loads, all Priorclaves are fitted with thermal interlocks (BS2646 requires a device preventing access until the load is cooler than 80°C)

- Door retention devices guarding against residual pressure are fitted in accordance with the UK Health and Safety Executive’s note PM73

- Regulation safety valves (BS6759) are fitted to all Priorclaves and set to ensure microbiological as well as physical safety

- Non-tip shelves are fitted on all front loading models

Autoclave Quality Certificates

Priorclave holds a number of accreditations and certifications. These include:

- ISO 9001 certified

- UKAS accreditation (ISO/lEe 17025:2017)

- ASME certification (American Society of Mechanical Engineers)

- National Board of Boiler &National Board Certificate of Boiler & Pressure Vessel Insp, 2015 on Pressure Inspectors certification

- Group insurance details

- PED Certificate to 2023ulations 1999 certification

- Emc Directive certification (EN50081-1 and EN50082-1)

compliance standards

- BS2646-1993

- BS5500 cat.3

- EN61010-2-41

- EN5008-1 / EN50082-1

- HSE Note PM73

- European Pressure Vessel Directive -97/23/EC