Does Our Lab Really Need a Jacketed Autoclave?

Most labs never even ask themselves this question. They’re painfully aware of the shortfalls of the autoclaves they’ve used: high purchase price, high utility bills, frequent maintenance downtime. But they rarely know that the root cause of most of that misery wasn’t the autoclave itself. The real culprit is that autoclave’s steam jacket.

Fortunately, most labs and industrial settings do not need a jacketed autoclave. A programmable non-jacketed autoclave will perform well for them—at a far lower cost and with much less hassle.

Steam Jacketed Autoclaves Explained

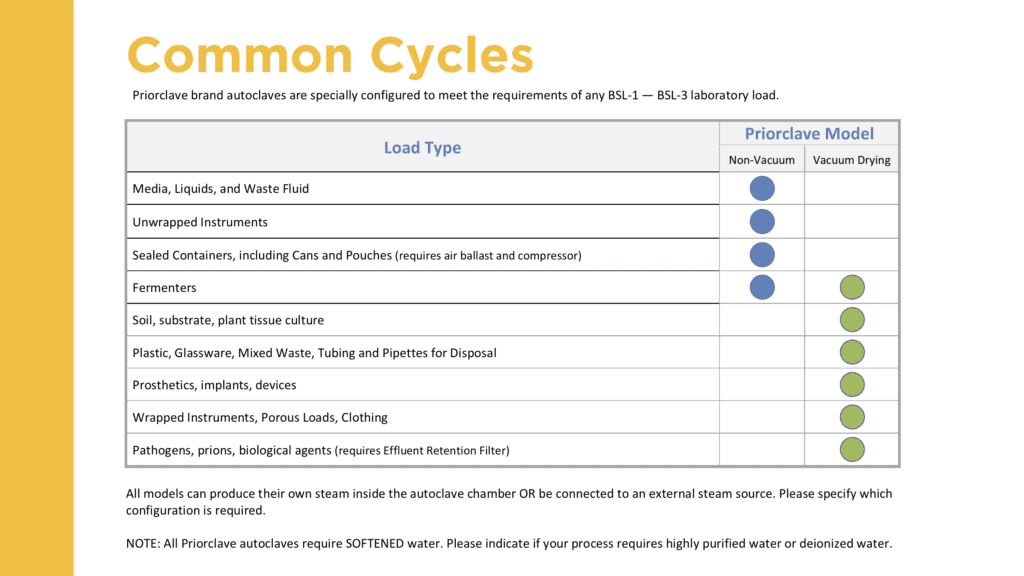

Every steam autoclave is fundamentally the same: It floods a sealed chamber with steam and holds it at a specific temperature and pressure for a given period of time. This combination of moist heat, sustained high temperature, increased chamber pressure, and time consistently kills spores and microorganisms, disinfects pathogenic waste, processes liquids, and sterilizes culture media, pipette tips, glassware, surgical instruments, and the like.

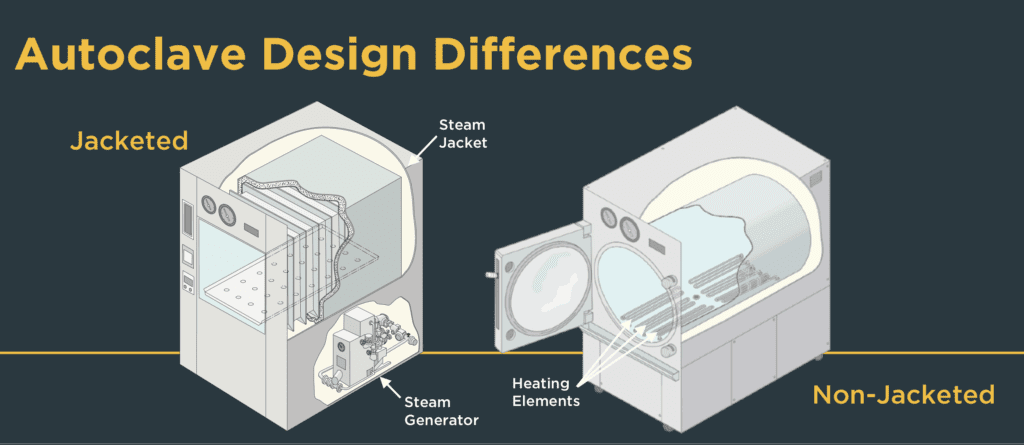

Many modern autoclave steam sterilizers, especially larger models, rely on a “jacketed” design to speed up this process. These units require an independent steam generator to supply their sterilizing steam. That steam is first routed through the “steam jacket,” which is a rectangular steel shell surrounding the rectangular pressure chamber. The steam then enters the sealed pressure vessel. This nested arrangement makes it possible to reach the sterilization temperature relatively quickly. At the end of the sterilization cycle, the jacket can then be flooded with cold water to speed cooling.

The result is an autoclave that is ideal for high-throughput 24/7/365 operation. It’s the preferred sterilization approach for hospitals and may be a good fit for medical or pharmaceutical labs with demanding schedules or a need for terminal sterilization.

But this comes at a cost.

The High Cost of Steam Jackets

Steam jacketed autoclaves are expensive to purchase, maintain, and operate. This starts with the manufacturing process. The jacketed design is complicated. It relies on specialized interdependent components, many of them proprietary. The jacketed pressure vessel is essentially double-walled, with the inner pressure chamber made of thick, reinforced steel. This extra layer increases both material and labor costs, resulting in a heavier unit that is more costly to build, ship, and install.

Once installed, a jacketed autoclave requires a fair bit of tender loving care. Quarterly maintenance visits typically require factory technicians and usually mean purchasing proprietary components. On top of that, jacketed autoclaves rely on independent steam generators. These constitute an entirely separate point of failure with their own maintenance schedule and upkeep.

Finally, it’s important to understand that jacketed autoclaves trade a small increase in throughput for a sizable increase in resource consumption. Speeding up processing requires more water and electricity per cycle, and often demands that the unit idle hot, consuming energy even when not in active use.

But this isn’t the only way to approach sterilization. Steam jackets are vital in high-throughput settings—but very few labs qualify as “high throughput.”

A Simple Non-Jacketed Alternative

Non-jacketed autoclaves have several key design advantages that make them less expensive to own, operate, and maintain than their jacketed counterparts. If you run fewer than five cycles per work day and focus on the following load types, then you have better options.

Non-jacketed autoclaves don’t have to use rectangular pressure chambers, instead opting for cylindrical pressure vessels.

These cope better with high pressure and temperature and can be safely fashioned from thinner steel with fewer reinforcing ribs. Because the entire system is less massive, there is no need for an expensive external steam source. Instead, non-jacketed autoclaves can rely on efficient in-chamber heating elements.

Non-jacketed autoclaves will often take longer to run complete sterilization cycles, because their efficient in-chamber heating elements need time to come up to temperature. A programmable control system can reduce the impact of these delays by running cycles overnight or warming up the autoclave prior to staff arriving in the morning.

Additionally, because there is no jacket to flood with cold water, most non-jacketed autoclaves rely on “natural” cooling. This takes longer, but can be accelerated with fans and vacuum vacuum operations, which accelerate processing for most load types (e.g., pipette tips, red bag waste, and other “dry” loads). That said, liquids, culture media, and other “wet” loads still usually take longer in a non-jacketed autoclave.

But even in labs that largely run “wet” loads, a non-jacketed autoclave usually proves to be a good value. Compared to similar-sized jacketed models, non-jacketed autoclaves cost 10 to 30 percent less to purchase. They use 70 percent less electricity and 95 percent less water on a daily basis. They have fewer moving parts that might fail, can often be repaired with readily available standard components, and generally need less than half as much regular maintenance.

Case Study: Jacketed vs. Non-Jacketed Laboratory Autoclave Efficiency

In fall of 2023, the University of Alabama at Birmingham (UAB) completed an in-depth metering study comparing the performance of their jacketed and non-jacketed autoclave sterilizers. They compared jacketed autoclaves configured to use minimal water and outfitted with the manufacturers’ “water saving features” against a non-jacketed Priorclave autoclave running as designed, with no additional “eco” features.

UAB found that, on average, their jacketed autoclaves used between 44 and 50 gallons of water per sterilization cycle. Meanwhile, their non-jacketed autoclave used less than 2 gallons per cycle. Similarly, while their jacketed autoclaves consumed 25 to 41 pounds of house steam per cycle, the non-jacketed autoclave used no additional house steam, generating all the steam they needed on their own.

Based on these findings, UAB estimated that the water to operate their jacketed autoclaves costs them $764 per autoclave per year, while the non-jacketed autoclaves used only $23 per autoclave per year. Given that they have more than 100 steam jacketed autoclaves on campus, they determined that steam-jacketed autoclaves were costing them an additional $74,000 annually with no corresponding benefit (given their use patterns and tasks). UAB further noted that this higher operating cost was in addition to a higher initial purchase price: a jacketed autoclave cost UAB roughly 37 percent more than its comparably featured non-jacketed equivalent. UAB noted anecdotal reports of energy and maintenance cost savings associated with adopting non-jacketed autoclaves (although these were not quantified in this study).

Does Your Lab Need a Jacketed Autoclave?

If you work in a hospital, have high-throughput applications, or require terminal sterilization for human use (as is the case in pharmaceutical production), you might still need a jacketed autoclave.

But if your facility runs five (or fewer) cycles per work day, values sustainable operations, wants to conserve natural resources, and needs to save money, then you probably don’t. Contact us to learn more and discuss finding the right autoclave for you and your lab.