Reliable Autoclave Sterilizers for Medical Device Research, Development, and Testing

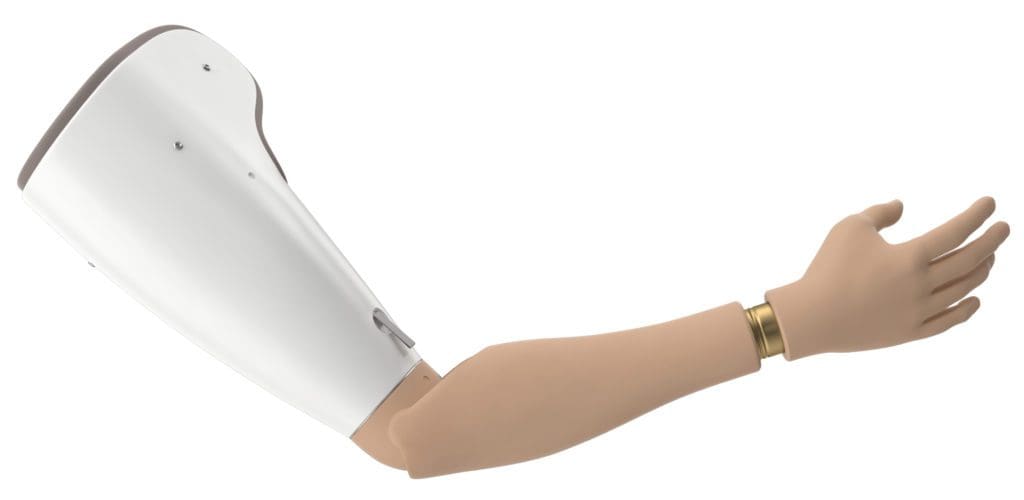

Engineers must consider reliability and lifespan when designing medical equipment, including prosthetics and other medical devices. Durable instruments and devices must withstand repeated use and many sterilization cycles. In the case of single-use surgical supplies, that equipment must maintain sterility and integrity after transport and long-term storage, potentially under poorly controlled conditions.

In many cases, an off-the-shelf environmental chamber is sufficient for this task. But there are some applications that require more rigorous testing. This is especially true when testing advanced synthetic materials, electronics, medical devices, or package integrity to ASTM standards (e.g., ASTM F1980).

Designers and engineers routinely use autoclaves to test prosthetics, devices, hospital equipment, and packaging for devices, instruments, and supplies. These accelerated aging tests yield valuable information about potential leaching, corrosion, and the long-term durability of plastics, epoxies, and different packaging designs.

In many cases, a standard environmental chamber is sufficient for this task. But there are some applications that require more rigorous testing. This is especially true when testing advanced synthetic materials, electronics, medical devices, or package integrity to meet ASTM standards (e.g., ASTM F1980).

Steam sterilization is vital to the design and development of new devices and prosthetics—just as it’s vital to any sterile setting. The heat and pressure inside an autoclave chamber create the perfect atmosphere for evaluating long-term performance, safety, and stability of medical equipment.

But the type of medical autoclave used to sterilize surgical instruments and implants in a healthcare setting prior to a procedure is almost never the right choice for the engineers and designers creating or testing the medical devices and surgical tools that will be used for that procedure.

Maintain a Clean and Sterile Environment for Developing Medical Devices

While steam-jacketed medical autoclaves are essential for hospital use, they are more often an obstacle to medical device development. Priorclave provides steam autoclaves that make medical device testing as easy and efficient as possible.

Hospitals, surgical suites and medical clinics need jacketed medical autoclaves because these are designed to meet strict FDA sterilization guidelines for surgical instruments and implants. Standard jacketed autoclaves do that job very well. But jacketed autoclaves are expensive—not only the initial purchase price, but also in terms of resource consumption and ongoing maintenance. Furthermore, they are designed for a single task and provide little operational flexibility outside the narrow range of healthcare-specific steam sterilization cycles.

Biomedical research and development labs need something different. R & D involves a much broader range of tasks, and requires steam autoclaves that are dependable, efficient, and flexible. Priorclave’s standard, non-jacketed research-grade tabletop and free-standing sterilizers allow for much longer cycle times, and greater variation in parameters (like pressure and temperature) during these cycles. These machines subject your prototypes to the same stress and strain as an FDA-approved jacketed medical-grade sterilizer—but in an easily automated and replicable fashion, without high maintenance and operating costs. As one medical device engineer put it: “When testing is easier, product development teams can run more test cycles. When lives are on the line, more product testing is always better.”

Case Study: Using Autoclaves for Product Component Testing

In 2015, a medical device manufacturer was pioneering a new robotics-assisted method for partial and total knee-replacement surgery. This innovation would ultimately reduce patient discomfort and risk, eliminate the need for repeated pre-op CT scans, and improve surgical accuracy. The method relied on several complex, reusable electronic instruments, including a specialized electrical sensor encased in a metal and plastic casing held together by epoxy.

Researchers initially tried using a standard medical sterilizer for durability testing, but discovered that their autoclave’s limited control system was impractical for this application. While it was possible to run up to six sterilization cycles per day, doing so demanded an unsustainable level of monitoring by a technician. In practice, the manufacturer rarely ran more than two or three cycles per day. After weeks, the designers had still completed only 70 sterilization cycles. That fell far short of their minimum benchmark—and they’d only tested a single prototype.

Priorclave North America outfitted them with a similarly sized non-jacketed research-grade steam autoclave. This model could functionally approximate the pre-surgical cycles a jacketed autoclave would run. More importantly, this Priorclave sterilizer came with the flexible Tactrol Control System (standard on all Priorclave machines), allowing for fine control of every operating parameter, extended cycle times, and automated cycle repeats.

Researchers immediately went from running one or two staff-supervised cycles per day to running 10 to 15 cycles per night—with no staff supervision required.

If You Need Help, Priorclave is Here: Service and Support for Your Autoclave Steam Sterilizer

Our dedicated team of seasoned experts is ready to discuss your autoclave purchasing decision, even if you are unsure about your specific needs. We can help you find the right sterilizer, whether it’s a tabletop model that’s ready to go, or a custom autoclave built specifically for your lab.

Priorclave prioritizes customer service and support. Our customers consistently report 93 to 100 percent satisfaction with their purchase over time—and that rating improves the longer they’ve owned the unit.

Every Priorclave sterilizer is covered by free lifetime remote technical support and consultation and one of the best warranty programs in the industry. Priorclave also maintains a global network of factory-certified authorized service agents.

Every Priorclave sterilizer is covered by free lifetime remote technical support and consultation and one of the best warranty programs in the industry. Priorclave also maintains a global network of factory-certified authorized service agents (ASAs).

When you are ready to discuss your equipment needs, we are as close as a call or click.