“Right-Sizing” Your Laboratory Autoclave: A Two-Part Method for Selecting an Appropriate Lab Autoclave

Nick Ciancio, founder of the University of Alabama at Birmingham (UAB)

Green Labs Program and UAB Sustainability Coordinator from 2019 to 2024

I. OVERVIEW

This whitepaper documents one method for conducting an autoclave usage study to support right-sizing an autoclave purchase for a research setting. In this case, that means purchasing autoclaves that meet the functional needs of all of our labs without wasting resources. Click here to download the PDF version of this whitepaper.

We developed this approach at the University of Alabama at Birmingham during the COVID pandemic, when changes in work schedules created an opportunity to analyze steam autoclave usage patterns on our campus and determine whether our autoclave practices fit our needs. The specific concern: was our choice of autoclave and associated practices making it difficult to meet our institutional sustainability goals?

Most research labs rely on an autoclave to ensure that their equipment, reagents, glassware, and other tools are sterile. The autoclave uses a combination of steam, pressure, and time to reliably kill or deactivate harmful bacteria, viruses, fungi, spores, and pathogens on lab items or in waste loads prior to disposal.

Maintaining this level of sterility can be extremely resource-intensive. Steam-jacketed autoclaves are ideal for most high-throughput environments (like hospitals) because they have the capacity to complete over 12 cycles in a work day. That high-throughput operation comes at an environmental and financial cost: steam-jacketed autoclaves—without water-saving features—can use hundreds to thousands of gallons of water per day, even while sitting idle.

One example: the University of California, Riverside, tracked autoclave water and energy consumption in their labs across several years. They found that, on average, their jacketed autoclaves used 648 gallons of water every day (approximately 236,000 gallons of water per autoclave per year). This was regardless of the number and types of sterilization cycles they ran. In one notable case, one of their autoclaves (functioning as designed) used 16,000 gallons of water over the course of a 39-day period during which it did not run a single cycle.

Jacketed autoclaves use large amounts of water because they are optimized for around-the-clock operation. But this throughput isn’t always necessary for research environments. While some labs work at this furious pace, most do not. It isn’t at all unusual for a research lab to run their autoclave just once each day. Lab autoclaves often sit idle for hours or days between cycles.

As an increasing number of labs and research institutions take the lead in decarbonization and sustainability efforts within their organizations, it becomes increasingly important to “right-size” our autoclaves.

II. BACKGROUND

The University of Alabama at Birmingham (UAB) is an internationally recognized R1 university. It ranks among the best funded research programs and faculty in the United States. UAB is noted for exceptional mentoring and training opportunities across the hundreds of labs in its 10 schools, 24 research centers, and numerous clinics.

UAB is also a global leader in sustainability in academic science. In the last seven years, UAB has steadily expanded its Green Labs program. This is a voluntary program that helps lab leadership implement efficiency measures that reduce environmental and economic costs without sacrificing research quality, lab safety, productivity, or the comfort of lab staff. In the last seven years, UAB’s Green Labs program has grown from a dozen participants to 150 labs.

At UAB, the vast majority of autoclaves are a shared resource, with multiple autoclaves available on each of several floors in most research buildings. Despite a noted commitment to sustainability, as of 2022, all of UAB’s more than 100 autoclaves were steam-jacketed models. These steam-jacketed autoclaves had water-saving features installed and were configured to use minimal water between cycles. Nevertheless, we were concerned about continuing to invest in jacketed-autoclaves, owing to their reputation for high resource consumption.

Few labs have an accurate sense of the resource consumption of their autoclaves. This is further complicated by the fact that different makes, models, and styles of autoclaves consume wildly varying amounts of water. Additionally, we had many anecdotal reports of maintenance issues with jacketed autoclaves at UAB. These were reportedly creating obstacles to timely research, as well as driving up costs. We wanted to be sure that the autoclaves we were purchasing were a good fit, justifying the cost and inconvenience.

III. METHODS: DATA COLLECTION

This whitepaper documents our method for conducting an autoclave usage study to support “right-sizing” an autoclave purchase for a research setting. This was a two-step process. The first step was usage pattern data collection via survey among lab staff. The second was documented metering of water consumption during the most common autoclave sterilization cycles used by those labs.

- Usage patterns: How often are the autoclaves used? Which types of cycles are most common? What issues arise around this use pattern, in terms of scheduling, maintenance, wait times for a shared autoclave to become available, and so on?

- Resource consumption: How much water and steam does a given style of autoclave actually use while running the types of cycles common among the surveyed labs?

i. Usage Data Collection

We selected six UAB buildings, which housed among them more than 50% of all the shared autoclaves on campus. At each unit, we posted user logs to collect data on:

- identity of the user and their lab

- date / time of use

- load size (full / half / less than half)

- cycle type (liquid / gravity)

- biohazard waste load (yes / no)

This data was collected over two periods: October 2020 to December 2020 and October 2021 to January 2022.

ii. Water Consumption Metering

In October 2023 we partnered with UAB’s Department of Environmental Health and Safety to document water consumption during the most common autoclave sterilization cycles. In order to do so, we took several autoclaves offline for one week. Each was fitted with a non-invasive ultrasonic water flow metering device (a Flexim Fluxus F601 Portable Multi-Functional Flow Meter). We then ran the most common autoclave use cases (as identified through the usage data collection survey). The metering device collected hundreds of data points per cycle, allowing us to determine average water and steam use per cycle type.

In the case of the non-jacketed autoclaves (which generate their own steam in-chamber) measuring water and steam consumption was simply a matter of monitoring the water influent, as this corresponded to the total water/steam consumption per cycle for the unit. For the steam-jacketed autoclaves (which get their steam from the building’s house steam supply and primarily use water for cooling), we monitored both the influent and the exfluent (noting that the exfluent would comprise both the exiting influent water and the condensed steam). We then used the measured influent as the “water consumption” for that cycle and the delta between influent and exfluent as a reliable estimate of the “steam consumption” for that cycle.

IV. DATA

i. Usage Data

Our usage survey captured 714 cycles across campus. Of the 714 logged cycles, 297 were liquid cycles and 389 were gravity cycles. (The remaining 28 cycles were either vacuum cycles or left unidentified on the user log.)

We found that researchers rarely used the autoclaves outside of traditional work hours (9am to 5pm). Most autoclaves were used once or twice per day. Some went more than a day without being used at all, and none ran more than four cycles in a given day. We also found that most autoclaves were usually run below capacity: only 43% of a building’s sterilization cycles were run at full capacity. In one building, the autoclave was run at full capacity just 4% of the time.

ii. Water Consumption Data

Over the course of the week-long metering study we monitored both jacketed and non-jacketed autoclaves through several cycles of each of the two most common cycle types (see Table 1 below).

On average, UAB’s jacketed autoclaves used between 44 and 50 gallons of water per sterilization cycle (depending on cycle type). The corresponding non-jacketed autoclave used less than 2 gallons per cycle (regardless of cycle type). While the jacketed autoclaves consumed 25 to 41 pounds of house steam per cycle, the non-jacketed autoclave used no house steam. (Non-jacketed autoclaves generate their own steam using an electrical in-chamber heater to convert a portion of the cycle water to steam.)

V. DISCUSSION

Based on these findings, we estimate that the water used to operate UAB’s jacketed autoclaves costs $764 per autoclave per year. Meanwhile, the water for UAB’s non-jacketed autoclaves is closer to $23 per autoclave per year. Given that we have more than 100 steam jacketed autoclaves on campus, our existing preference for steam-jacketed autoclaves translates to an additional $74,000 in annual spending. This ongoing cost is additional to the higher initial purchase price of a jacketed autoclave: a jacketed autoclave costs UAB roughly 37% more than its comparably featured non-jacketed equivalent.

We recognize that cost isn’t everything. Research labs can and should pursue behavioral changes in the lab that minimize the impact of their autoclaves. For example, making sure to use water-saving “idling modes” between cycles and educating staff to eliminate unnecessary autoclaving (e.g., preventing autoclaving of waste loads that don’t need pre-disposal sterilization, as defined by EHS regulations). UAB pursues many of these already. The metering portion of our study presumed that any autoclave cycle was indeed necessary and that the autoclaves used essentially no resources between cycles.

With efficient autoclaves and good lab practices, water / steam costs will be relatively low for both jacketed and non-jacketed autoclaves. In the context of a university budget, the “higher” price for water / steam consumption incurred while operating a jacketed autoclave is not especially high.

Nonetheless, in UAB’s case, we note that our usage patterns do not justify the higher purchase price and added operational costs associated with jacketed autoclaves. Our autoclaves are mostly used during the workday. They rarely run at full capacity, with many used less than once per day. Anecdotally, when researchers did find themselves needing to run a sterilization cycle but unable to access an autoclave, it was usually because so many of the jacketed autoclaves were offline for maintenance. During our survey, 64% of respondents reported experiencing problems with the autoclaves. Most estimated that the average autoclave outage was three weeks.

At UAB, we are spending tens of thousands of dollars on jacketed autoclaves with no corresponding benefit. Given our usage patterns and reliability questions, the added cost of a jacketed autoclave does not appear to be justified.

VI. IMPACT ON DECARBONIZATION

Although this study focuses on water consumption, it does have implications for decarbonization efforts. Electrification is a key strategy for decarbonizing laboratories. House steam generation relies heavily on natural gas.

When natural gas is used to heat water to generate steam, it results in emissions of about 0.05307 pounds of CO2 per pound of steam. Given that it takes around 45 pounds of steam to run a sterilization cycle in a jacketed autoclave, the carbon footprint of sterilizing that load is roughly equivalent to driving the average American sedan 2.5 miles. Meanwhile, in-chamber steam generation relies on electrical heaters, which can easily be powered by low-carbon or zero-carbon sources.

Given that an institution like UAB has roughly 100 autoclaves campus-wide, continuing to use steam-jacketed autoclaves attached to house steam is the same as driving 250 miles per day for no reason. From that perspective, it makes sense for institutions with decarbonization goals to consider non-jacketed autoclaves.

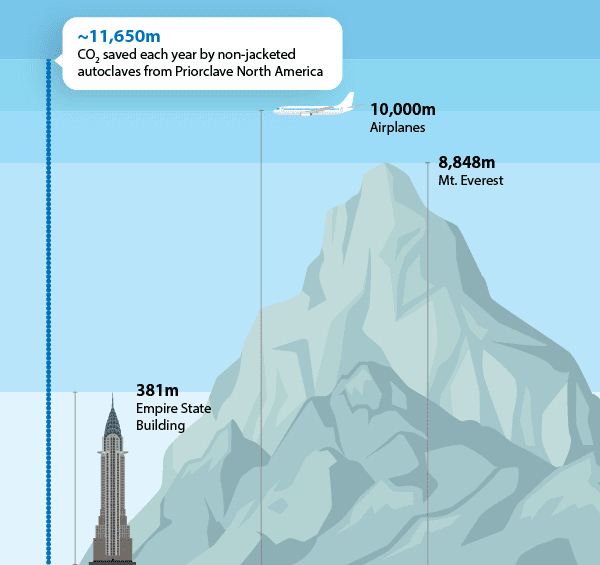

A visualization of the amount of CO2 Priorclave non-jacketed autoclaves keep out of the atmosphere each year. If stacked as one-metric-ton spheres, that tower of prevented pollution would reach 11,650m—teller than Mt Everest, and higher than passenger planes fly

VII. LIMITATIONS

There were several limitations to this study which can likely be addressed by other institutions doing their own studies. For example, although UAB noted many anecdotal reports of high electrical utility and maintenance cost associated with jacketed autoclaves, these were not quantified in this study. We similarly note that, for water metering, in-line metering is superior to ultrasonic water flow metering. In our case, in-line metering proved cost-prohibitive, in terms of both installation costs and the impact to researchers’ work.

Finally, this study was limited in time and scope, and thus may not capture changes in usage patterns that occur throughout the academic year. The metering portion of our study presumed that autoclave cycles are only run when necessary, and that autoclaves use essentially no resources between cycles. Neither of these are the case in real life.