The key to autoclave reliability is to start with an autoclave tailored to suit your tasks, facility, and staff. Unsure what you need to get your job done? Give us a call; we’re happy to help you specify the ideal device and process for your facility.

Core Options

Priorclave’s core options will help you customise your unit for the tasks in your lab. These options include programmable cycles, pulsed freesteaming for complicated loads, load sensed process timing for liquid loads, or just changing which way the door is hinged.

Tactrol 5 or 10 Program Memory

Tactrol 5 or 10 Program Memory- Tactrol 10 Program Memory Upgrade

- Setting Lock Key Switch

- Pulsed Freesteaming

- Load Sensed Process Timing

- Automatic Waterfill Systems

- Other Hand Door

Monitoring Options

Priorclave’s Monitoring Options make it easier to narrow in on the data you need to keep an eye on, including temperature, pressure, and error codes.

Tactrol Data Printer

Tactrol Data Printer- Load Temperature Monitoring

- Chamber Pressure Monitoring

- Graphic Recorder – Datalogger with LCD screen

- Ethernet Port – Connect Network Cable to Autoclave Printer (pairs with Graphic Recorder)

Heating/Cooling and Water Quality Options

Priorclave’s Heating/Cooling and Water Quality Options make it possible to better control the environment inside your steriliser.

Water/Steam Jackets

Water/Steam Jackets- Scale Prevention Systems

- Purified Water Level Sensor

- Accelerated Heating

- Air Ballast System (External Air Supply)

- Dual Electric and Steam Heating

- Fast Cooling Systems

- Air Intake Filter System

- Steam Intake Filter System

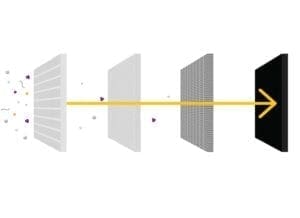

- Exhaust Filtration System

- Drain Condensers

Vacuum Options

Priorclave’s Vacuum Options help eliminate air pockets in complex loads and speed cooling and drying.

- Combined Pre-Cycle Vacuum and Vacuum Cooling

- Vacuum Drying